How Hospitals and Medical Centers Benefit from Specialized Commercial Roofing

Hospitals operate around the clock, relying on stable indoor environments to protect patients and sensitive equipment. A building’s roof plays a direct role in that reliability. Investing in specialized commercial roofing solutions helps healthcare facilities maintain uninterrupted service, control costs, and meet strict safety regulations.

Continuous Operation Requires Reliable Protection

Unlike standard businesses, hospitals cannot pause operations for roof repair. A single leak can disrupt surgery schedules or damage expensive diagnostic machines. Specialized systems designed for healthcare settings emphasize redundancy, drainage, and insulation. These features keep critical areas safe even during maintenance or severe storms.

Professional teams plan work in phases to limit noise and vibration. This approach ensures that patient areas remain quiet and uncontaminated while crews handle sensitive materials such as adhesives or membranes.

Energy Efficiency and Climate Control

Large medical campuses consume significant energy for lighting, climate control, and sterilization. Reflective or insulated commercial roofing materials reduce heat absorption and stabilize indoor temperatures. Over time, consistent energy savings offset installation expenses.

Energy-efficient roofs also help maintain temperature consistency in operating rooms and laboratories, where even minor fluctuations can affect performance. Proper sealing and ventilation protect air-filtration systems from moisture buildup that might encourage bacterial growth.

Compliance With Safety and Hygiene Standards

Healthcare buildings must meet unique regulatory expectations for cleanliness and infection control. Roof membranes resistant to mold, mildew, and standing water support these goals. Drainage designs prevent water pooling that could attract pests or lead to air-quality issues.

Licensed specialists understand how roofing choices affect compliance audits. Using the right materials can simplify documentation for accreditation bodies and local health authorities. Thorough maintenance records from experienced technicians demonstrate adherence to environmental standards.

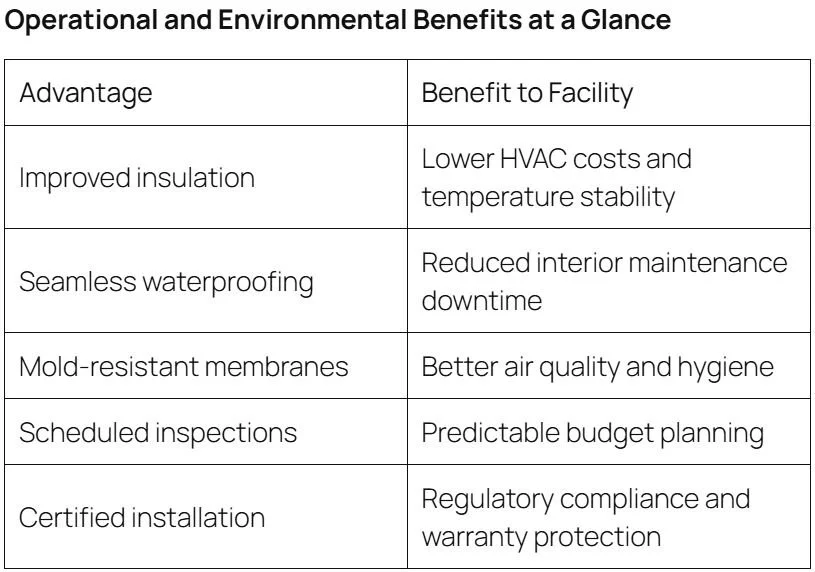

Long-Term Durability and Budget Stability

Hospitals plan budgets years in advance, and predictable maintenance costs matter. High-performance roofing systems extend service life through enhanced weather resistance, reducing unexpected capital expenditures. Regular inspections and preventive roof repair catch small issues before they evolve into major disruptions.

Durable materials such as modified bitumen or single-ply membranes withstand heavy equipment loads from HVAC units or solar arrays. Coatings formulated for ultraviolet resistance further extend roof longevity under harsh Texas sun exposure.

Reducing Liability Through Professional Oversight

Certified roof installers follow stringent safety and waste-management procedures that protect staff and visitors. These measures limit liability and demonstrate environmental responsibility. Hospitals that maintain ongoing service contracts with roofing specialists benefit from prioritized response times after storms, ensuring swift mitigation of potential leaks or insulation damage.

Final Insight

Healthcare facilities depend on roof infrastructure that never fails. Partnering with an experienced commercial roofing provider ensures safe operations, lower maintenance costs, and long-term resilience. Specialized materials and documented roof repair programs keep critical services running without interruption, protecting both patients and assets.

Important Maintenance Advice for Commercial Roof Longevity

Commercial roofing is a significant investment for any business owner. Whether you oversee a single retail location or manage multiple office complexes, your roof is essential to protecting operations. With the right maintenance practices, you can extend roof life, prevent costly roof repair, and keep tenants or employees safe.

Schedule Regular Inspections

The National Roofing Contractors Association (NRCA) recommends at least two inspections per year. Certified professionals check seams, flashing, and drainage points that are often overlooked. After major storms, inspections are especially important. Wouldn’t you rather catch a small seam split early than pay for repairs after water infiltrates insulation and damages ceilings?

Keep Drainage Clear

Most premature failures on flat commercial roofing systems come from blocked drains. Standing water adds weight and raises the risk of leaks. Sloped roofs also need attention; gutters and downspouts must stay clear to prevent water intrusion. Clean drainage channels regularly and confirm water flows away from the building.

A Costly Example

Imagine a retail center in Dallas with a flat TPO roof. The property manager neglected seasonal cleaning. After a thunderstorm, pooled water seeped into the insulation, forcing multiple tenants to close for days. Sadly, a single afternoon of preventive cleaning could have saved thousands in lost revenue.

Focus on High-Risk Areas

Certain spots on a roof wear out more quickly than others. These high-stress areas face constant exposure to heat, moisture, and movement, which makes them more vulnerable to early failure. Paying close attention to these zones during inspections helps detect problems sooner, improve maintenance efficiency, and prevent costly business disruptions. Knowing where to look makes every inspection more effective:

Flashing around HVAC units and skylights

Seams and laps on membrane systems

Fasteners and protective coatings on metal roofs

Edges and corners exposed to wind uplift

Track Repairs and Warranties

Maintain a written log of all roof repair and inspection activity. This documentation helps with warranty claims and gives contractors a history of past problems. Many manufacturers require proof of consistent maintenance to honor coverage, so good records protect your financial investment as much as the roof itself.

Inspect the Attic for Warning Signs

Look for damp insulation, dark stains, or musty odors that point to hidden leaks. These signs help your roofing contractor trace moisture to its source more quickly. Condensation on nails or rafters is another red flag. Small pools of water or warped wood mean the problem has persisted for some time. Checking your attic regularly keeps you informed and allows you to alert the contractor before damage spreads further. According to the Center for Environmental Innovation in Roofing, with routine inspections and timely maintenance you can stretch a roof’s usable life to 20 years or more.

Local Support for Businesses

In regions like West Texas, Northwest Arkansas, and Northern Louisiana, weather extremes demand proactive care. A local commercial roofing team provides inspections, roof repair, and preventive maintenance tailored to regional conditions. By relying on experienced professionals, property managers gain reliable protection and long-term savings.

Commercial roof longevity is not luck. It is the result of consistent inspections, clear drainage, and expert roof repair performed by qualified contractors. Putting off inspections and necessary roof repair leaves businesses in the south-central U.S. holding the bag for higher expenses.

5 Questions to Ask Before Hiring a Roofing Contractor

Choosing the right contractor for your commercial roofing project can make all the difference. Whether you’re patching up an existing system or planning a full replacement, asking the right questions up front helps you find someone who knows what they’re doing and who’ll follow through. Commercial roofing is more complex than residential work, so it’s worth spending a little extra time making sure your contractor fits.

Are You Licensed and Insured for Commercial Projects?

Don’t assume all roofing companies meet the same standards. For commercial work, it’s critical that the contractor is properly licensed in your area and carries both general liability and workers’ compensation insurance. Not only does this protect their crew– it protects your building, too.

What Kind of Experience Do You Have With This Type of Roof?

Commercial roofs aren’t one-size-fits-all. Materials like TPO, modified bitumen, or metal panels each come with their installation process. Ask whether the contractor has hands-on experience with your roof type and if they’ve worked on projects similar in scale. Familiarity with insulation systems, drainage design, and large-format layouts can directly impact how well the work holds up– and how often you’ll need future roof repair.

Can You Share References From Recent Jobs?

Hearing from past clients is one of the best ways to judge a roof contractor’s reliability. Ask to speak with other business owners who’ve hired them recently. Find out how the contractor communicated, handled changes, or dealt with any hiccups along the way. Solid references and a few successful projects under their belt go a long way in helping you feel confident.

What Are Your On-Site Safety Practices?

On a commercial site, safety isn’t optional– it’s essential. Ask about fall protection, training procedures, and how they manage tools and equipment. Contractors should have a written safety plan and follow OSHA guidelines closely. The more proactive they are about protecting their crew and your property, the more smoothly your project will run.

Do You Offer a Warranty and Ongoing Support?

A good contractor doesn’t disappear after the job is done. Ask what kind of warranty they offer– not just on materials, but on the work itself. Also, find out if they offer roof repair follow-up services like inspections or seasonal maintenance. A strong warranty paired with solid post-installation support helps ensure that your investment is protected.

Don’t Skip the Timeline and Communication Details

Aside from licenses and references, you’ll also want to understand how your contractor manages the job itself. What’s the expected timeline? How do they handle material delivery or weather delays? How will they keep you updated– daily reports, weekly meetings, or milestone check-ins? Knowing how and when you’ll get updates can help avoid misunderstandings.

Taking the time to ask these questions helps you choose a roofing contractor who’s not just qualified– but also reliable and easy to work with. In commercial roofing, you need more than just technical skill. You need a partner who communicates clearly, respects your property, and stands behind their work every step of the way.

Conduct Walkthrough Inspections Before Roof Replacement

Before committing to a full roof replacement, a commercial roofing walkthrough inspection is one crucial step that often gets overlooked. It may sound basic, but this simple visit can prevent major headaches down the line. If you manage a warehouse, a school, or a commercial plaza, you know there’s no room for guesswork. A walkthrough gives your contractor the chance to understand the roof as more than what’s listed on a quote or blueprint.

Why the Walkthrough Is More Than Just a Formality

Roof repairs aren’t small jobs. They bring in permits, heavy equipment, scheduling conflicts, and costs that rise quickly if surprises pop up. A proper walkthrough looks beyond the surface. One contractor recently uncovered severe rust in a metal deck at a logistics center. The issue wasn’t visible from the surface but would’ve caused serious safety concerns mid-project. Walkthroughs can reveal whether a full replacement is truly needed.

What Contractors Look For

There’s a lot more to these visits than just walking across the roof. A seasoned roofing contractor checks the membrane for punctures, the flashings for lifting edges, and the transitions between roof planes for signs of wear. They’ll tap on suspect sections, test for moisture, and inspect any patched or modified areas. Older buildings might have had solar panels added, units relocated, or materials swapped over the years.

The Access Factor

Sometimes, the biggest challenge is getting to the roof itself. Contractors of commercial roofing use the walkthrough to plan how equipment, materials, and crews will reach the site. Can a crane access the lot? Will deliveries block staff entry points? Are there restrictions on working hours in mixed-use buildings? These questions may seem small now, but ignoring them can lead to delays, cost overruns, and frustrated tenants.

Know the Roof’s History to Avoid Future Mistakes

A walkthrough is also a conversation. A contractor will want to hear about previous leaks, areas that ice over in winter, and repairs that didn’t hold up. These details fill in the blanks that even the most detailed inspection can miss. When the roofing team understands the building’s history, they’re better equipped to avoid repeating past failures.

Match Materials to Conditions, Not Just Budgets

If the roof handles heavy foot traffic from maintenance crews or HVAC teams, the membrane must be more durable. Buildings in hot zones need UV-resistant systems; industrial facilities might require chemical-resistant surfaces. A walkthrough allows the contractor to recommend systems that fit the specific needs.

Beyond the Roof Surface

The inspection doesn’t stop at the edge of the membrane. Walls, parapets, scuppers, and even adjacent building elements matter. For example, if scuppers are undersized or blocked, water backs up and compromises the entire system. A full-system view ensures you’re not just replacing a roof– you’re upgrading the performance of everything around it.

Walkthroughs aren’t just a box to check– they’re the blueprint for a smooth, efficient, and successful roofing project. Skipping them means building on assumptions. Taking the time to do them right means your project starts with answers, not questions.

Perform Flat Roof Inspections Every Season

Flat roofs may be popular in commercial roofing, but they bring their own set of challenges. Their low slope looks sleek and maximizes usable space, but it also invites pooling water, debris buildup, and early membrane wear. Regular inspections aren’t just recommended– they’re essential. If you wait until a leak shows up inside the building, you’ve already missed your chance to prevent it.

Why Flat Roofs Face Seasonal Strain

Each season tests your roof in different ways. In spring, thawing ice reveals hidden cracks. Summer heat softens roofing materials, often leading to blisters or seam separation. Come fall, leaves and windblown debris collect in drainage areas. And winter? Between snow weight and freeze-thaw cycles, flat roofs take a beating. These conditions don’t just stress the surface—they gradually weaken the entire system. And that can mean unexpected roof repair just when your building can least afford the downtime.

What a Thorough Inspection Should Include

A true inspection is more than a casual look with a flashlight. A seasoned roofing contractor checks for early membrane wear, loose seams, blistering, and standing water. We also inspect edge flashing, roof penetrations, and nearby equipment—HVAC units and vents can cause trouble if seals have degraded. Many of these issues aren’t obvious from the ground, and they’re often missed in generic walkthroughs by building staff.

Roof Type Dictates Inspection Strategy

Your material matters more than you might think. EPDM rubber responds differently to stress than TPO or modified bitumen. One flat roof we checked last fall had edge shrinkage common with aging EPDM. It wasn’t leaking yet, but it was pulling away from the flashing. If you don’t understand the behavior of your specific roofing system, you won’t know where to look– or what to fix before it gets worse.

Why Commercial Buildings Need Consistent Oversight

Commercial roofs cover more than just surface area—they often support HVAC platforms, skylights, solar arrays, or heavy foot traffic. These stress points can weaken over time, especially near seams or transition areas. Some of our clients also face insurance or leasing obligations that require regular maintenance logs. Scheduled inspections not only meet those requirements– they avoid surprises.

Choosing a Roofing Contractor Who Knows Flat Roofs

Experience matters here. You want someone who doesn’t just glance around but knows where to dig deeper. Tools like thermal cameras, drones, and moisture scanners help us identify problems without tearing anything open. But the tech only works if you know how to use it—and more importantly, how to act on what it shows. A good contractor won’t push unnecessary repairs. They’ll give you a real picture of what needs attention and what can wait.

You wouldn’t skip HVAC service or fire alarm checks—your roof deserves the same treatment. It protects your inventory, your staff, and your business continuity. Treating inspections as routine, rather than reactive, keeps your operations running smoothly and your repair budget in check. In the long run, those hour-long visits each season can prevent a lot more than just water damage.